NiAl cladding hmoov nrog lub zog sib txuas

Kev piav qhia

Peb txaus siab los qhia ob yam khoom raws li NiAl hmoov: KF-2 thiab KF-6.Ob yam khoom no siv qhov sib txawv ntawm NiAl hmoov thiab muaj cov yam ntxwv tshwj xeeb thiab kev siv.

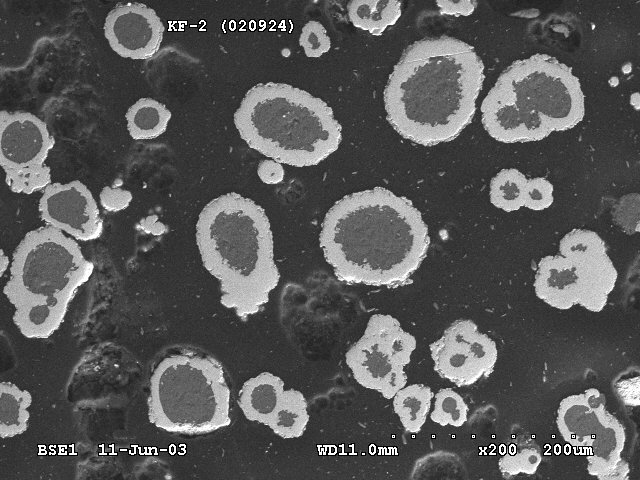

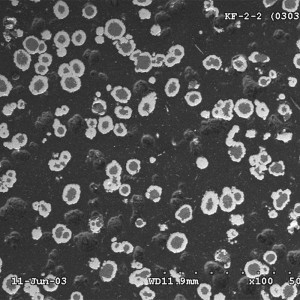

KF-2 siv NiAl82/18, uas muaj 82% Ni thiab 18% Al.Cov khoom no yog tsim rau cov ntawv thov nrog qhov siab tshaj plaws ua haujlwm kub ntawm 650 ° C.Nws muab cov tuab, machinable, oxidation-resistant, thiab hnav-resistant txheej nrog tus kheej kev sib sau ua ke.Muaj ib txwm muaj cov tshuaj tiv thaiv exothermic thaum lub sij hawm txau, uas ua rau muaj kev sib raug zoo zog zoo dua li Ni5Al cov ntaub ntawv.KF-2 yog qhov tsim nyog rau kev kho thiab rov tsim cov pa roj carbon steel thiab corrosion-resistant steel, thiab tseem tuaj yeem siv rau kev sib txuas cov txheej ntawm ceramics thiab cov ntaub ntawv hnav.

KF-6 siv NiAl95/5, uas muaj 95% Ni thiab 5% Al.Cov khoom no tsim nyog rau cov ntawv thov uas muaj qhov kub siab tshaj plaws ntawm kev ua haujlwm ntawm 800 ° C thiab tuaj yeem siv tau siv ntau txoj kev txau xws li nplaim taws, APS, thiab HVOF.Nws tseem muab cov tshuaj tuab, machinestable, oxidation-resistant, thiab hnav-resistant txheej nrog tus kheej kev sib sau ua ke.Muaj ib txwm muaj cov tshuaj tiv thaiv exothermic thaum lub sij hawm txau cov txheej txheem, ua rau muaj kev sib txuas zoo heev.KF-6 tseem tuaj yeem siv los kho thiab rov tsim cov pa roj carbon steel thiab corrosion-resistant steel, nrog rau kev sib txuas cov khaubncaws sab nraud povtseg ntawm ceramics thiab cov ntaub ntawv hnav.

Hauv cov ntsiab lus, KF-2 thiab KF-6 yog NiAl hmoov-raws li cov khoom lag luam uas muaj kev sib raug zoo zoo thiab hnav tsis kam.KF-2, uas muaj qis feem pua ntawm NiAl hmoov (NiAl82/18), yog tsim rau cov ntawv thov nrog qhov siab tshaj plaws kev khiav hauj lwm kub ntawm 650 ° C, thaum KF-6, nrog ib tug ntau dua feem pua ntawm NiAl hmoov (NiAl95/5), tuaj yeem tswj tau qhov kub siab tshaj li 800 ° C thiab tuaj yeem siv tau los ntawm ntau txoj kev txau.Ob qho khoom lag luam yog qhov zoo tagnrho rau kev kho thiab rov tsim cov pa roj carbon steel thiab corrosion-resistant steel, nrog rau kev sib txuas cov khaubncaws sab nraud povtseg ntawm ceramics thiab cov ntaub ntawv hnav.Qhov kev xaiv ntawm KF-2 thiab KF-6 yog nyob ntawm cov kev cai tshwj xeeb ntawm daim ntawv thov thiab qhov siab tshaj plaws ua haujlwm kub yuav tsum tau ua.

Cov khoom zoo sib xws

| Hom | Khoom npe | AMPERIT | METCO/AMRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404 NOS | ||||

| KF-6 | NiAl95/5 | 282 | 9 56450 nsq | NCO-109 | 906 ib |

Specification

| Hom | Khoom npe | Chemistry (wt%) | Hardness | Kub | Khoom & Daim Ntawv Thov | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | • Nplaim, APS, Max.Ua haujlwm kub 650 ° C. •Dense thiab machinable oxidation resistant thiab hnav resistant txheej. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | • Nplaim, APS, HVOF, Max.Ua haujlwm kub 800 ° C •Dense thiab machinable oxidation resistant thiab hnav resistant txheej | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | •Siv rau txav tau qhov chaw sib khi thiab cov nplhaib sib khi • Nws tuaj yeem siv los ua cov khoom sib txhuam qis | ||||||||

| KF-21 T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | • Nplaim, Max.Kev khiav hauj lwm kub 480 ° C 1. Hnav cov ntaub ntawv ntawm turbo compressor • Muaj feem xyuam rau nickel alloy thiab steel qhov chaw • Cov khoom uas muaj cov ntsiab lus graphite yog tsim rau titanium yam tsis muaj ntug •Cov ntsiab lus graphite siab yuav txhim khu lub lubrication kev ua tau zoo • Cov ntsiab lus nickel siab yuav txhim kho kev yaig kuj • Cov khoom zoo sib xws yog txawv vim txawv OEM specifications | ||||||||

| KF-22 T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | • Nplaim, APS, tsis xwm yeem •Nws tuaj yeem siv rau melting crucible, davhlau ya nyob twg sealing nto thiab pwm nto raws li kev tiv thaiv txheej | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | • Nplaim, APS, tsis xwm yeem •Resistance rau hammering, yaig, abrasion thiab zawv zawg abrasion | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | • nplaim taws, tsis xwm yeem •Resistance rau hammering, yaig, abrasion thiab zawv zawg abrasion | ||||||||

| KF-91 Fe | Fe-WC | 4 | 27 | 9.5 ib | Bal. | 5.5 | HRC 40 | ≤ 550ºC | • Nplaim, APS, tsis xwm yeem, Max.Ua haujlwm kub 815 ° C. • Hnav cov khoom tiv thaiv txheej, uas tuaj yeem siv rau kev kho lub tank nres | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | • Nplaim, APS, Max.Kev khiav hauj lwm kub 980 ° C. • Plasma txau nrog kev sib txuas ntawm tus kheej | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr + Al: 20, Ni + Co: 75 | HRC 20 | ≤ 900ºC | •APS, HVOF, irregular, Max.Kev khiav hauj lwm kub 980 ° C. •Nws muaj feem xyuam rau kev kho cov txheej txheem kub kub los yog hnav / ua haujlwm tsis raug | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤650ºC | • Kev sib koom ua ke ntawm tus kheej, txheej txheej nyuaj rau daim ntawv thov bearing •Tough, nrog zoo corrosion kuj thiab cuam tshuam kev ua tau zoo •Siv rau tshuab qhov chaw, bearing rooj thiab valve | |||||||

| KF-31 | Ni-diatomite 75/25 | • Nplaim, APS, tsis xwm yeem, Max.Ua haujlwm kub 650 ° C. •Rau grindable foob txheej, nrog rau cov khoom txav txav tau, cov nplhaib sib tsoo, cov ntaub ntawv tsis tshua muaj kev sib txhuam | ||||||||||||