MCrAlY Alloy nrog kub tsis kam

Kev piav qhia

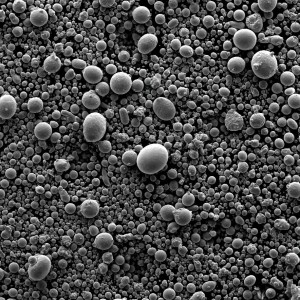

Hom Tshuaj:KF-301 KF-308 KF-309 KF-336 KF-337 KF-339… Hom: Gas atomized

Hmoov Khoom:Chemical Composition: MCrAlY (M = Fe, Ni, los yog Co) Particle Loj: -45 +15 µm Purity: ≥ 99.5%

Daim ntawv thov:MCrAlY Alloy hmoov yog dav siv nyob rau hauv high-temperature daim ntaub ntawv vim lawv cov khoom tshwj xeeb.Lawv feem ntau yog siv los ua cov tsho tiv no hauv metallurgical yob, kub dip dab dej yob, thiab kho cua sov rauv yob.Tsis tas li ntawd, lawv tau siv nyob rau hauv kev lag luam aerospace rau kev tsim cov roj turbine Cheebtsam, tshav kub tiv thaiv, thiab aero engine hniav.

Cov yam ntxwv ntawm MCrAlY Alloy

1.High Temperature Resistance: MCrAlY Alloy hmoov muaj kev tiv thaiv zoo rau qhov kub thiab txias.Cov cuab yeej no ua rau lawv zoo tagnrho rau siv rau hauv cov ntawv thov kub xws li roj turbines, cov cua sov kho cua sov, thiab cov yob metallurgical.

2.Antioxidant Properties: MCrAlY Alloy hmoov yog cov resistant rau oxidation ntawm qhov kub thiab txias, ua rau lawv zoo tagnrho rau siv nyob rau hauv hnyav ib puag ncig uas oxidation yuav tshwm sim, xws li nyob rau hauv roj turbines thiab tshav kub shields.

3.Hot Corrosion Resistance: MCrAlY Alloy hmoov muaj kev tiv thaiv zoo heev rau kub corrosion, ua rau lawv zoo tagnrho rau siv nyob rau hauv daim ntaub ntawv uas cov khoom raug corrosive ib puag ncig ntawm qhov kub thiab txias.

4.Thermal Barrier Substrate: MCrAlY Alloy hmoov feem ntau yog siv los ua thermal barrier substrates vim lawv cov thermal conductivity thiab thermal expansion zog.Lawv tau siv ua ke nrog cov txheej txheem ceramic los tiv thaiv cov khoom siv los ntawm qhov chaw kub kub.

Zuag qhia tag nrho, MCrAlY Alloy hmoov yog ntau yam khoom siv uas nthuav tawm cov khoom kub zoo heev, ua rau lawv zoo tagnrho rau siv ntau yam kev siv thoob plaws kev lag luam sib txawv.Lawv cov yam ntxwv tshwj xeeb, suav nrog kev kub siab ua haujlwm, cov khoom tiv thaiv antioxidant, kub corrosion kuj, thiab thermal barrier substrate zog, ua rau lawv muaj kev xaiv nrov rau kev siv kub.

Cov khoom zoo sib xws

| Hom | Khoom npe | AMPERIT | METCO/AMRY | WOKA | PRAXAIR | PAC |

| KF-301 | ||||||

| KF-308 | NiCrAlY | ib 9621 | ||||

| KF-309 | NiCoCrAlY | |||||

| KF-336 | CoCrAlSiY | |||||

| KF-337 | CoNiCrAlY | ib 9954 | ||||

| KF-339 | CoCrAlYTaSiC |

Specification

| Hom | Khoom npe | Chemistry (wt%) | Hardness | Kub | Khoom & Daim Ntawv Thov | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | Y | Ta | Si | C | Co | Ni | |||||

| KF-301 | •APS, HVOF, detonation-phom, spherical • Cov tsho tiv no kub kub | |||||||||||

| KF-308 | Nickel Chromium Txhuas Yttrium Alloy | 25 | 11 | 1 | Bal. | HRC 20-30 | ≤ 950ºC | •Metallurgical yob, kub dip dab dej yob, kho cua sov rauv yob. •Aero cav hniav, roj turbine, tshav kub tiv thaiv | ||||

| KF-309 | Nickel Cobalt Chromium Txhuas Yttrium Alloy | 25 | 6 | 0.5 | 22 | Bal. | HRC 20-30 | ≤ 950ºC | • Kub kub kuj, antioxidant. • Kub corrosion kuj. •Thermal barrier substrate | |||

| KF-336 | Cobalt Chromium Txhuas Silicon Yttrium Alloy | 29 | 7 | 0.5 | 3 | Bal. | HRC 20-30 | ≤1000ºC | • Kub kub kuj, antioxidant. • Kub corrosion kuj, substrate | |||

| KF-337 | Cobalt Chromium Txhuas Yttrium Alloy | 23 | 6 | 0.4 | Bal. | 30 | HRC 20-30 | ≤1050ºC | • Kub kub kuj, antioxidant. • Kub corrosion kuj, thermal barrier substrate | |||

| KF-339 | Cobalt Chromium Txhuas Yttrium Alloy | 24 | 7.5 | 0.8 ua | 10 | 0.8 ua | 2 | Bal. | ≤1100ºC | •APS, HVOF, detonation-phom, spherical •Metallurgical yob, kub annealing rauv yob. •Aero cav rotor hniav, qhia hniav thiab roj turbine hniav | ||