Cobalt Base Alloy nrog tiv taus hnav thiab corrosion

Kev piav qhia

KF-3321 yog cobalt-based alloy hmoov nrog zoo hnav tsis kam thiab kub-kub oxidation kuj.Nws yog tsim los ntawm cobalt, chromium, tungsten, npib tsib xee, silicon, thiab carbon, thiab tej zaum kuj muaj me me ntawm txhuas, niobium, tantalum, thiab lwm yam hlau alloy.

Hmoov Khoom

Particle Loj:KF-3321 muaj qhov loj me me ntawm -140 txog +325 mesh, uas ua rau nws haum rau ntau daim ntawv thov uas yuav tsum muaj qhov loj me me.

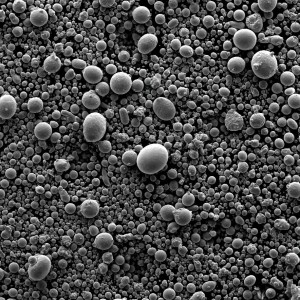

Hom:KF-3321 yog cov roj atomized hmoov, uas txhais tau tias nws yog tsim los ntawm melting lub alloy thiab ces atomizing nws nrog high-pressure gas.Qhov no ua rau cov hmoov zoo ib puag ncig, uas muab cov dej ntws zoo thiab ntim ntim.

Kev sib xyaw:KF-3321 yog cobalt-based alloy hmoov uas muaj cov feem pua ntawm cobalt, uas ua rau nws zoo heev hnav tsis kam.Qhov sib ntxiv ntawm chromium thiab tungsten ntxiv txhim kho nws cov hnav tsis kam thiab kub-kub oxidation kuj.Nickel, silicon, thiab carbon muab ntxiv zog thiab corrosion kuj rau cov hlau.

Daim ntawv thov

KF-3321 yog cov hmoov txhuas muaj ntau yam uas tuaj yeem siv rau hauv ntau qhov kev lag luam rau cov ntawv thov uas xav tau kev hnav zoo heev thiab kub-kub oxidation tsis kam.Qee cov ntawv thov siv xws li:

High-temperature siab li qub:KF-3321's high-temperature oxidation resistance ua rau nws yog ib qho khoom siv zoo tshaj plaws rau kev kub siab li qub.

Pom hniav:KF-3321's hnav tsis kam thiab toughness ua rau nws haum rau siv nyob rau hauv cov hniav saw, uas yuav tsum tau ib tug nyuaj cov ntaub ntawv uas muaj peev xwm tiv taus qhov kev nyuaj siab thiab strain ntawm txiav.

Extrusion Screws:KF-3321's hnav tsis kam thiab kub oxidation tsis kam ua rau nws xaiv zoo rau kev siv cov ntsia hlau extrusion, uas yuav tsum muaj cov khoom siv uas tuaj yeem tiv taus qhov kub thiab txias ntawm cov txheej txheem extrusion.

Zoo ib yam li St12:KF-3321 muaj cov khoom zoo sib xws rau St12, cov pa roj carbon tsawg feem ntau siv hauv kev lag luam tsheb.Txawm li cas los xij, KF-3321 muaj qhov zoo dua hnav tsis kam thiab kub-kub oxidation tsis kam tshaj St12, ua rau nws muaj kev xaiv zoo tshaj rau cov ntawv thov uas yuav tsum tau hnav tsis kam thiab kub siab.

Zuag qhia tag nrho, KF-3321 yog cov hmoov hlau ua haujlwm siab uas muaj kev hnav zoo heev thiab kub-kub oxidation tsis kam.Nws cov khoom siv ntau yam ua rau nws haum rau ntau yam kev siv hauv ntau yam lag luam.

Cov khoom zoo sib xws

| Hom | Khoom npe | AMPERIT | METCO/AMRY | WOKA | PRAXAIR | PAC |

| KF-331 | CoCrMoSi | 340 | 66/3002 | CO 109/1247 | T400 | |

| KF-333 | CoCrMoSi | 342 ib | 68/3001/4800 | CO 111/1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | Zoo li 344 | ib 4060 | TIAB SA 106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 ib | 45 x40 | CO105/CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Specification

| Hom | Khoom npe | Chemistry (wt%) | Hardness | Kub | Khoom & Daim Ntawv Thov | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | CoCrMoSi | 8 | 2.6 | 28 | Bal. | HRC 54 | ≤840ºC | • Hnav tsis kam, khawb kuj • Corrosion kuj | ||||

| KF-333 | CoCrMoSi | 17.5 Nws | 3.4 | 35 | Bal. | HRC53 | ≤840ºC | • Hnav tsis kam, khawb kuj • Corrosion kuj | ||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 ua | 10 | 1 | Bal. | HRC 30 | ≤840ºC | •Valve seat • Cov kabmob • Hniav • Zoo ib yam li St1 | ||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | Bal. | HRC45 | ≤840ºC | •PTA, APS, HVOF, laser cladding, kheej kheej • Kub siab li qub, pom hniav, extrusion screws • Zoo ib yam li St12 | |

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | Bal. | HRC 40 | ≤840ºC | •PTA, APS, HVOF, laser cladding, kheej kheej •Engine li qub, kub siab qhov tseem ceeb, turbo cav hniav • Zoo ib yam li St6 • Zoo hnav tsis kam nyob rau hauv qhov kub thiab txias | ||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | Bal. | HRC55 | ≤840ºC | • Turbine hniav • Cov kua dej li qub •Valve seat | ||

| KF-3324 | CoCrWCNiSi | 25.5 ib | 7.5 | 0.5 | 10.5 | 1 | Bal. | HRC 30 | ≤840ºC | • Extrusion pwm • Roj turbine hniav | ||

| KF-3325 | CoCrWCNiSi | 21.0 Nws | 5 | 0.1 | 1 | 1.6 | 2.4 | Bal. | HRC 50 | ≤840ºC | •PTA, APS, HVOF, laser cladding, kheej kheej • Kub hnav tsis kam • Lub tsheb kauj vab li qub • Nws tus kheej ntws | |